Benefits of Using Geofoam in Pool Wall Construction

- Consistent product performance

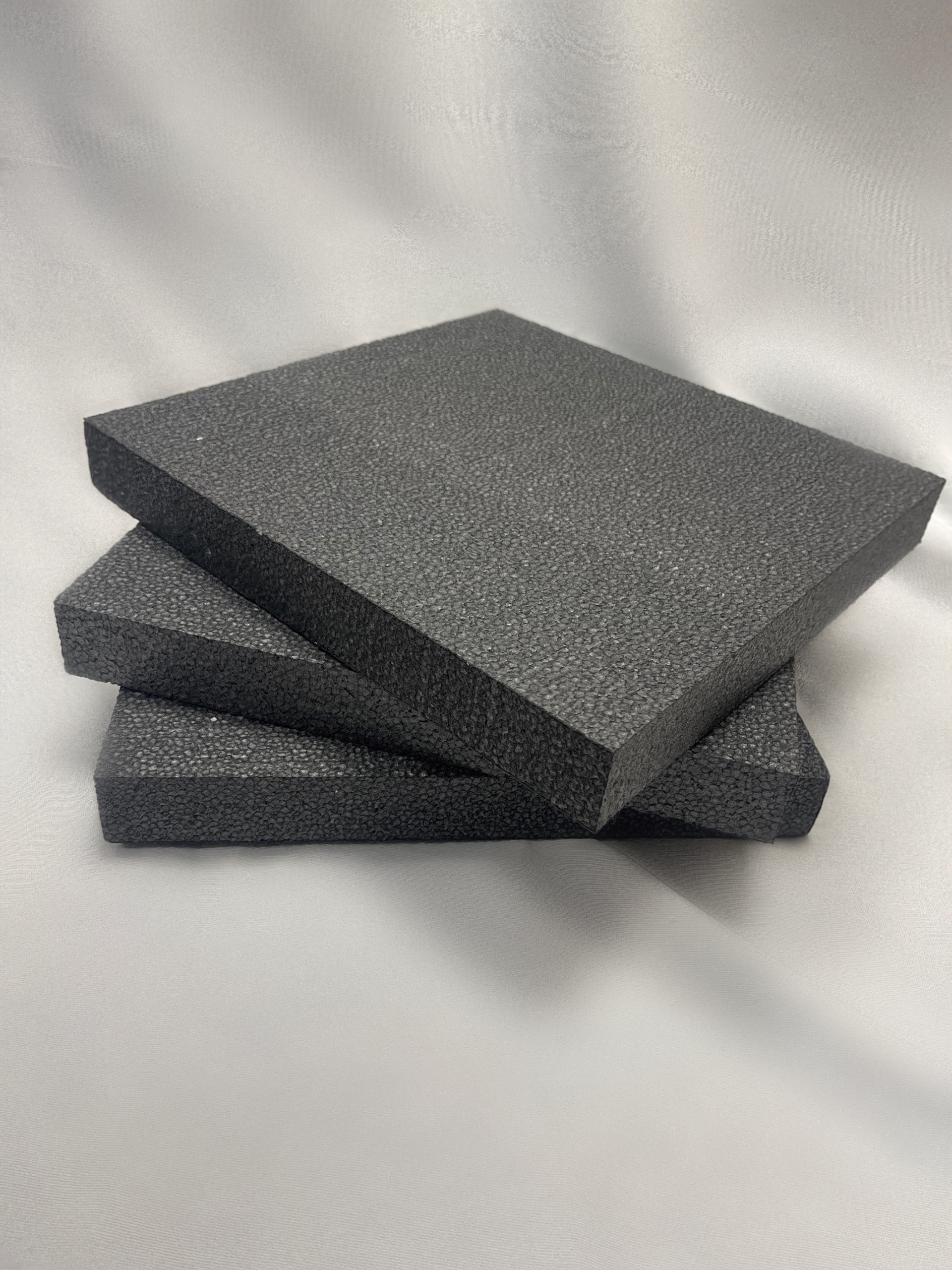

- Adherence to the ASTM D6817 standards

- Versatility to be used for many construction applications

- Low affinity for water (only 2% - 4% water absorbency)

- Ease of use, including the ability to be cut at the job site

- Light weight coupled with a high density-to-load ratio (320 – 2680 pounds per square foot)

Outer Shell

The Geofoam was cut in the field so workers could have an easier time accessing the necessary pieces to make lining the exterior of the pool’s concrete shell. Because of the loose and shifting soils in Texas, Geofoam is very effective, providing the proper resistance and stability needed to avoid cracking, as Gunite is a relatively fragile product. Excess expansion and contraction would cause the Gunite lining to become damaged.

Another interesting fact: Gunite and Shotcrete can be sprayed directly on Geofoam! It seems as though we learn a new way to use our products every week, and appreciate our customers sharing them with us.

Geofoam for swimming pools is just one more way to gain cost-savings through the use of labor and materials. Geofoam has been used worldwide for under-support for rail beds, airport runways, streets, highways, and sidewalks. We’ve reported on the varied uses for Geofoam from artisan construction to bridge entry construction and embankment support.

If you have a project that is calling for soil stabilization and foundational support and stabilization, think Geofoam. If you’re on the Eastern Seaboard, think Poly Molding.

Just pick up the phone or stop by and we’ll talk through your project and we’ll let you know if we can help.