Civil engineering projects that require embedded retaining walls often rely on secant pile wall construction to accomplish the stabilization of embankments, large commercial below ground storage space (basements). Secant walls are also used for the protection and stabilization of in-ground tanks as well as other buried structures.

While there are numerous methodologies in which to construct secant walls, they all require the initial review of groundwater table location, soil conditions, design life intentions, the height of the retained site, and deflections and propping options.

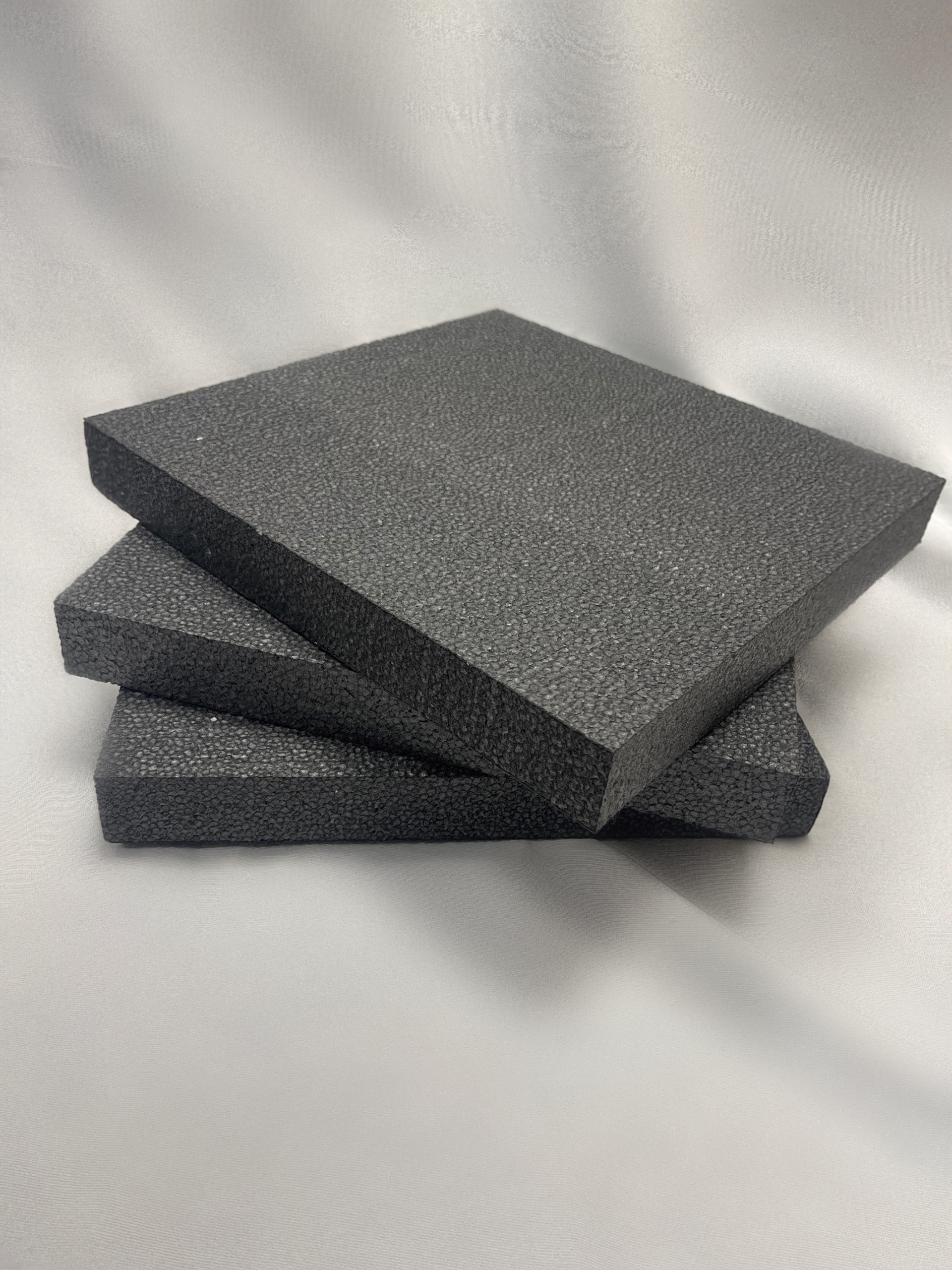

Often secant pile wall construction relies on wood form, while others use EPS Geofoam formation. As mentioned, there are various methods of constructing pile walls, and this excerpt from Piling Contractors sums them up rather well.

Soldier pile walls (cast in situ concrete bored, CFA or driven steel) – piles are installed at wide spacing’s (can be up to 5 – 8 pile diameters depending on soil conditions). The soil between piles is retained typically by timber lagging or by shotcrete applied to the exposed earth face during excavation. This wall type is not suitable where high water pressures or flows exist in the soil to be retained. This is usually the simplest, fastest and cheapest type of embedded retaining wall often used for temporary works.

Contiguous pile walls (cast in situ bored or CFA) – this wall method is often used in permanent applications. Structural piles are installed at close spacing’s typically with a 100mm gap between piles. The soil is therefore exposed during excavation but will often self support temporarily due to “arching”. This method is suitable in a variety of soils where groundwater lies below the maximum excavation depth.

Secant pile walls (hard / soft, hard / firm or hard / hard, cast in situ bored or CFA). A guide wall is required for this method of construction to ensure that piles are accurately located to achieve an interlock (or secant) cut into the adjacent pile. A secant pile wall uses interlocking male and female cast in situ piles to produce a retaining structure. Construction is carried out sequentially with primary (female) piles installed first then secondary (male) piles cut into the primary piles forming a continuous wall.

A hard / soft wall uses a weak concrete or grout for the female pile, which is usually unreinforced. This wall type provides some degree of water retention but is not watertight. Hard / Firm and Hard / Hard secant walls use the same construction process, however, the primary pile is cast from either weak mix concrete (typically 5 – 15 MPa, Hard / Firm wall ) or full strength concrete (hard / hard wall). The primary pile may also be reinforced. The construction sequence becomes particularly critical when needing to cut segments of 40 MPa concrete piles to allow installation of the secondary pile. High torque drill rigs and specially designed cutting tools are required.

This video, courtesy of Australian Company Piling Contractors provides an excellent review of the construction of secant pile construction.

EPS Geofoam secant pile wall construction is becoming very popular due to their ability to cut construction time and conserve financial resources. Regardless of your construction project, Poly Molding can assist in providing the necessary EPS materials quickly and affordably.

For more information on what we can do for your next deep excavation or retaining wall project, feel free to call us. We’d be happy to assist you through the entire process.

Lest we forget, the image (above) is courtesy Universal Construction of Washington State.