Governing bodies have rules, regulations, and guidelines for just about everything, including Geofoam. The State of New York Department of Transportation has such guidelines for the use of geo-technical supplies and equipment.

An excerpt from the manual is stated here:

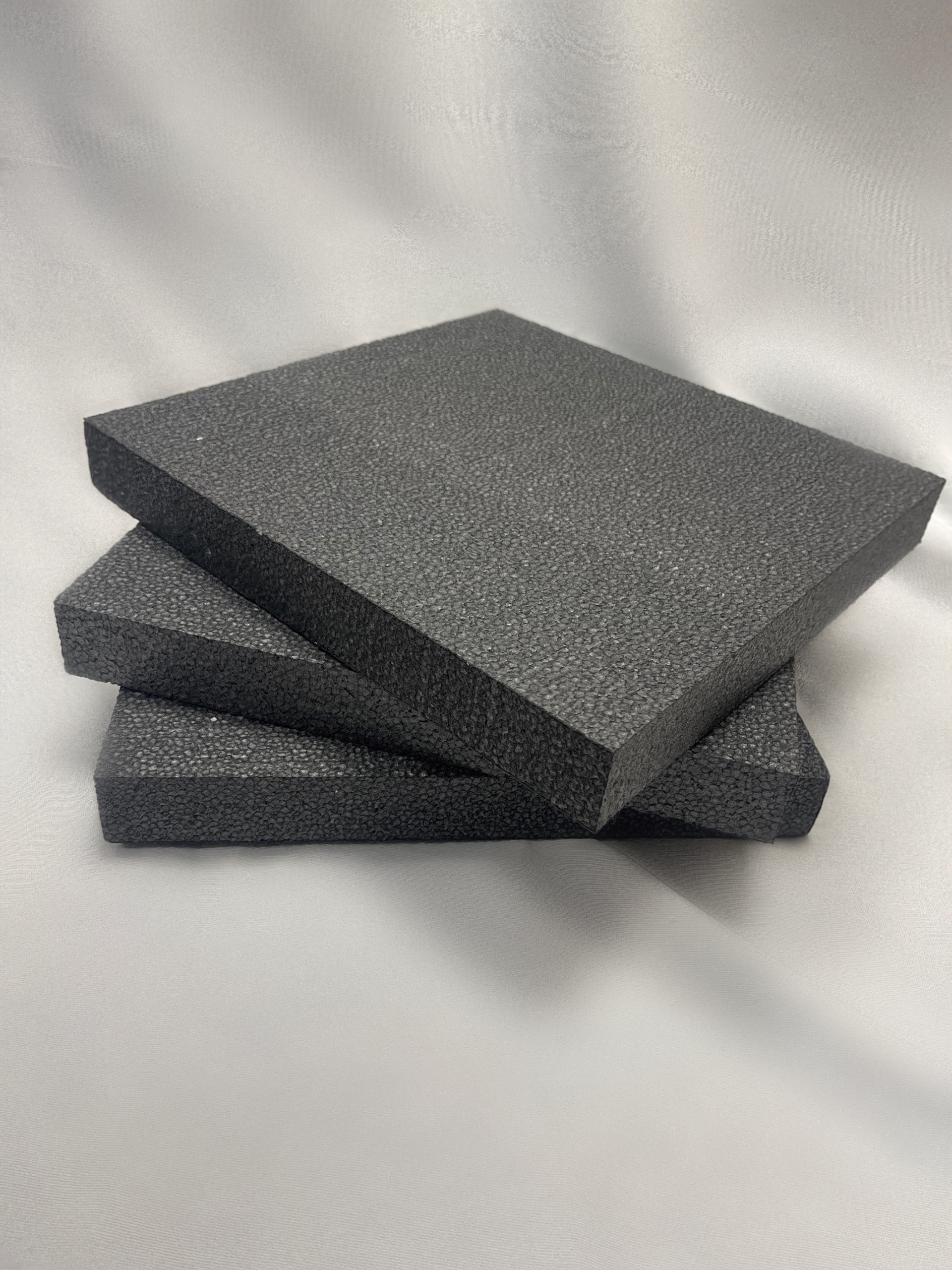

- EPS has a density that is less than 1% of typical soil fills. By using this extremely lightweight material in an embankment section over a deep, soft organic or clay soil deposit, significant time and cost savings may be achieved as compared to other foundation stabilization and settlement mitigation techniques. When properly designed as backfill, EPS blocks exert little to no lateral load on retaining structures.

- A typical block measuring 2 ft x 4 ft x 8 ft (0.6m x 1.2m x 2.4m) at a density of 1.25 pcf (0.2 kN/m3) weighs 80 lbs (36 kg). On site, EPS blocks may be easily unloaded by two laborers and placed into position.

- The composition of an EPS block allows field cutting and trimming by a hand-held “hot wire” apparatus, hand or power saws to produce desired shapes.

- This manual provides personnel in design and construction general information on EPS material and proper installation techniques.

As with any DOT project, there are oversight specifications from concentration of soils, density of the EPS, design, and project monitoring.

The criteria for project submittal is also outlined and is extremely detailed. You can learn more about it by downloading the official booklet.

Instrumentation and Monitoring

EPS fills may be monitored during and after construction to verify the performance of the foundation soils and/or the EPS mass itself. The Geotechnical Engineering Bureau will determine what types of monitoring equipment (e.g. settlement platforms, tilt plates, vertical or horizontal extensometers) should be provided and installed as part of the construction contract.

Here you can learn the ongoing project monitoring from actual operations to post-construction for performance verification.

The Verrazano Bridge

This project tested our mettle – the toll entrance ramp to the Verrazano Bridge. With the New York State Department of Transportation guidelines in-hand, the construction firm handling the project specified the materials requirements and we at Poly Molding were glad to supply them.

Here’s an excerpt from the MTA reports.

Construction on the Verrazano Bridge upper deck replacement project began in early March to replace the 50-year-old steel with higher-tech, lighter weight orthotropic steel. A continuous structure without expansion joints that can leak and deteriorate, the new deck is expected to have a longer lifespan than the original deck, built in 1964.

In the first of four construction stages, the MTA has removed 100,000 square feet of existing deck and begun installing the new orthotropic deck on the Staten Island side of the bridge during overnight work.

With the Metropolitan Transportation Authority covering the day to day management of the projects, they began on time and on budget, but with 50 years of wear and addition to HOV lanes, Toll entrance, and embankments (where Geofoam was used) the project finished on time as well as successful in accomplishing their mission.

Poly Molding is proud to have had a part in the project.