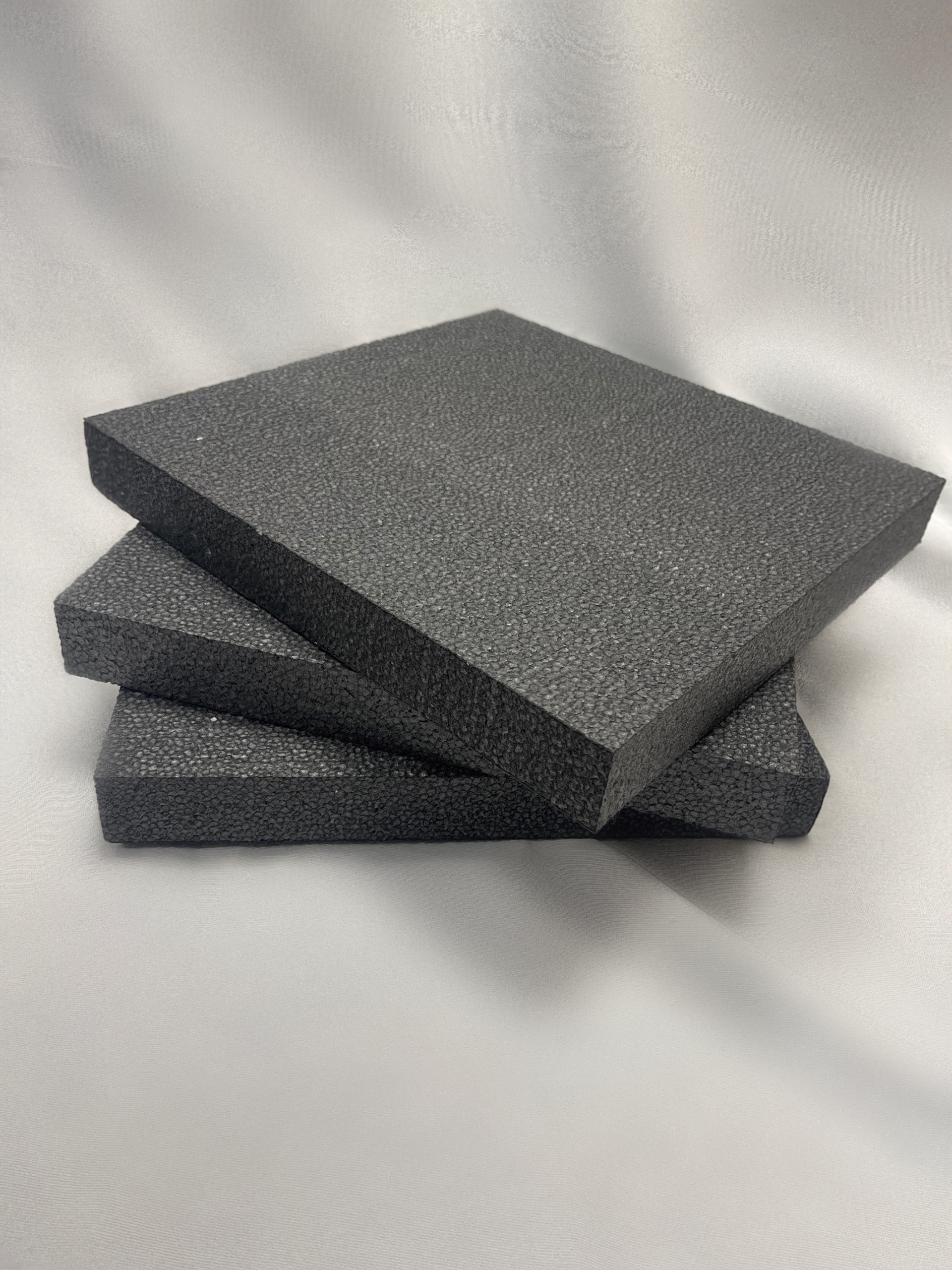

Since the 1930s, EPS Geofoam has been in the construction industry. The discovery of Expanded Polystyrene, which is 30 times lighter than soil, gave rise to a slew of new applications, including several applications in the construction sector. It is presently mostly utilized as insulation, but it is also employed as a structural filler in above and below-grade application as an alternative to soil.

The Importance of EPS Geofoam in Construction

EPS geofoam has a wide range of compressive resistance – Because of its lightweight qualities and ability to withstand a considerable capacity, geofoam is popular among architects, engineers, and builders. It barely weights 0.7 to 2.85 pounds per cubic foot, whereas dirt might weigh 110 to 120 pounds per cubic foot. When compared to foundation soils, structural foam blocks are a better solution. At a 1% strain, its compression resistance ranges from roughly 317 to 2,678 pounds per square foot. Because of its great compressive strength, geofoam is extremely robust and resistant to damage.

EPS geofoam is environmentally friendly – As green-conscious construction becomes more popular, builders are increasingly turning to EPS geofoam for its environmentally friendly properties. The fill material is completely recyclable and does not include any hydrochlorofluorocarbons or formaldehyde. Furthermore, it is a very efficient thermal insulator, reducing overall energy consumption and, as a result, the carbon footprint of many structures. Depending on the project requirements, EPS geofoam can also be made with a specific percentage of recycled content from previous geofoam blocks.

EPS geofoam blocks are used to construct stadium seats, landscapes, highways, and other structures – Aside from providing insulation for a variety of buildings, the possibilities for geofoam blocks are limitless and incredibly diverse. Geofoam blocks, for example, may be stacked to make stadium seats. These low-moisture, long-lasting blocks may also be used to support various landscapes and constructions, such as pool decks and rooftop gardens. Because of its capacity to absorb vibrations and high-impact compression, geofoam is also a popular fill material for highway foundations.

These and other factors make EPS geofoam a sustainable important material in the construction industry. For more information regarding EPS geofoam please contact us at info@polymoldingcorp.com or at (973) 835-7161.

Contact us at (800) 229-7161 or (973) 835-7161.