Think back to the last time you strolled down a pier. Did you spend much time thinking about how it was constructed? Most people assume piers are made strictly of wood and possible concrete at the base. However, geofoam has emerged as one of the best pier building materials. It is quite possible geofoam will be used for the construction of piers of all different types and sizes in the years to come, surpassing other building materials for myriad reasons. Let us take a closer look at why geofoam is one of the top building materials for piers in the United States and elsewhere.

The Merits of Geofoam for Building

Geofoam is garnering widespread praise for its stability, reliability and longevity in the context of construction. Geofoam is now considered to be one of the top materials used for the construction and support of piers and other water-based structures. Geofoam is superior to soil in that it significantly reduces the load placed on the substrate. After all, it does not make sense in the context of physics to add more weight to what is essentially a bridge constructed over water. This is precisely why geofoam will likely be used in pier construction for decades to come.

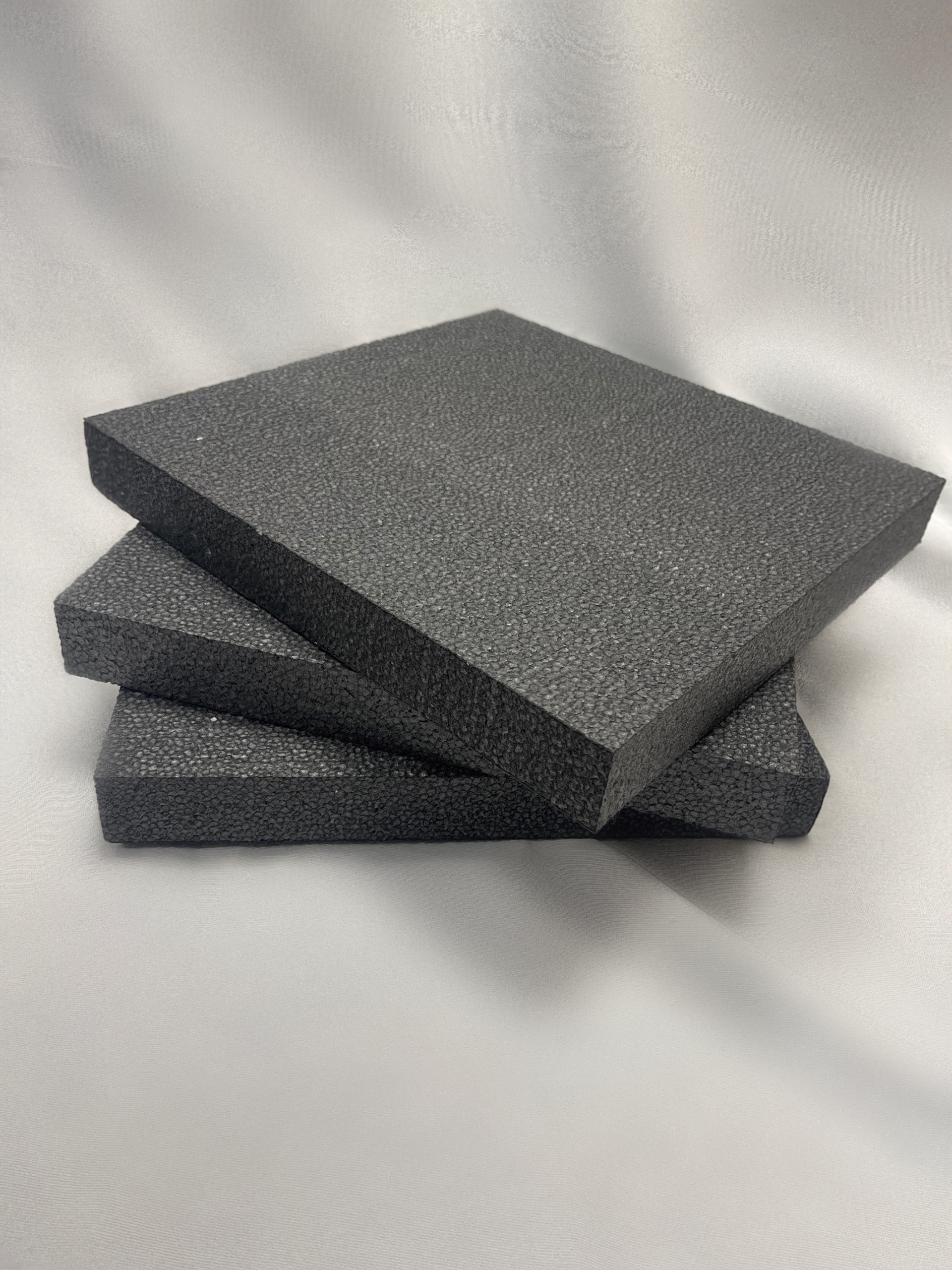

Add in the fact that geofoam foam blocks do not wash away with the water current as occurs with soil and other building materials and there is even more reason to opt for this unique building and support material. EPS geofoam has a closed-cell structure that limits water absorption; with proper drainage, weight gain is not expected. The material’s water-resistant nature is demonstrated by its frequent use in floating structures, such as piers.

EPS Geofoam Blocks are Easy to Work With

Aside from its comparably light weight, geofoam is also favored over other building materials as it remains in place better than soil and other options. A bonus is there is no need to use any type of specialized equipment to install geofoam blocks and keep them in place. The comparably minimal logistics concerns and machinery requirements really do make geofoam that much more desirable than soil and other building materials. EPS geofoam blocks’ rectangular cuts are created quite easily with the use of a hotwire cutter, resulting in a comparably efficient installation.

Geofoam’s Role in Building Pier 55 and Other Piers

In a city of roughly 8.4 million people with a density of about 27,000 citizens per square mile, there is not a whole lot of room for expansion in New York City. NYC can always raze current structures and rebuild them, but that does not do a lot for creating new space.

In residential construction, one of the best returns on investment is to turn ‘dead’ space into valuable, functional ‘living’ property. Building a gazebo in the middle of a lawn for example, or even expanding a deck further into the yard. That is the same premise New York City took with their pier projects, turning space on the Hudson River into enjoyable, functional, environmentally friendly spaces.

Of course, there are some real hurdles to jump when building on water. Poly Molding had the pleasure to be involved in the Pier 55 construction for an open-air structure that is set to open in the Spring of 2021. Obstacles, subsequent innovations, and the use of geofoam are what ultimately made this project a success.

Geofoam also known as Expanded polystyrene fill was integral in the soil bedding of pier 55. Anywhere from 12” inches and up to 2’ Ft of geofoam were used to achieve the complex design of this fine piece of Architecture. EPS19 was applied across the concrete deck of this pier to help create a drainage system and soil bedding for the landscaping elements.

Poly Molding was also proud to be part of other piers constructions such as Pier 26 and Pier 57 In New York City. What makes Poly Molding’s Geofoam such a versatile product are the different applications for the product whether is to build a slab, stabilized slopes, retain a wall or lighten the load of a structure, Geofoam continues being the trending building material of the past, present and future.