A Closer Look at the Differences Between EPS and XPS: Manufacturing

What About the R-value Retention?

The Management of Moisture

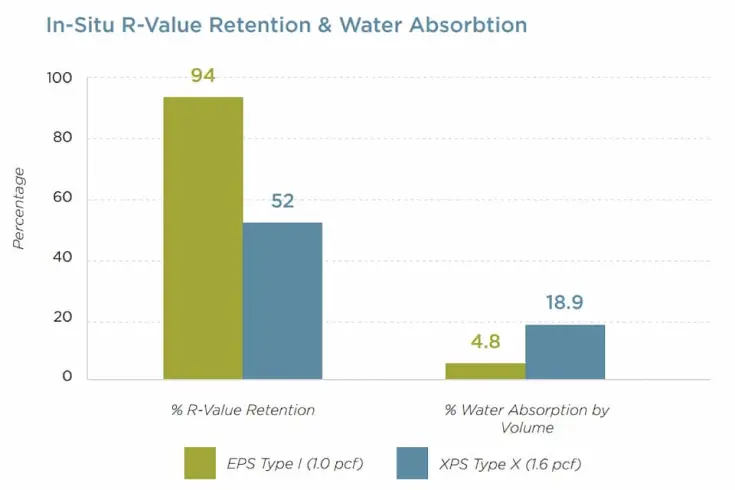

When people search the web for “insulation companies near me”, they key in on those that provide materials that are elite in terms of moisture management. EPS has comparably rigid insulation that is closed cell with an elevated tolerance that ensures moisture is resisted. In fact, field studies show EPS absorbs less moisture than anticipated.

Merely one-half of a percent is absorbed by EPS in a 15-year span, meaning it really is the best insulation for attic and also the best insulation for walls. Furthermore, when moisture moves into tiny cavities, EPS has a superior ability to expel that moisture.

Add in the fact that EPS has drying potential and XPS does not have such potential and there is even more reason to choose EPS. Drying potential is particularly important in the context of thermal insulation as it helps ensure the optimal thermal resistance, also known as R-value, is maintained amidst extensive exposure to moisture and other threats.

Can Both be Recycled?

Cost in the Context of R-value

Customization

Bonding Capability

The Impact on the Environment

Expanded Polystyrene is superior to Extruded Polystyrene in the context of the environment as EPS has never and likely will never be made with HCFCs that compromise the environment. Furthermore, those looking to preserve our fragile planet favor EPS as it does not use any type of dye. Add in the fact that EPS can be constructed with recycled content and there is even more reason to favor EPS over XPS.

In contrast, XPS typically contains dyes along with branding elements. In terms of the use of recycled materials, XPS is comparably inconsistent. The specific XPS product and manufacturer determines the level of recycled material used.

The Issue of Durability

EPS can be constructed in several different densities with the potential to reach a compressive strength upwards of a whopping 8,640 pounds/feet along with an impressive 10,800 pounds/feet of flexural strength. Though EPS is 98% air and uber-light, it is quite strong. Add in the fact that EPS is superior to XPS insulation R-value thanks to its laminated poly facer application to board for enhanced durability and impact resistance and there is even more reason to choose EPS.

Interested in learning more about Ploy Molding’s alternative product to XPS? Our POLY RITE Expanded Polystyrene product can be your project’s next geofoam solution.