When it comes to construction, the materials you choose can significantly impact project timelines, costs, and long-term outcomes. One of the most notable advancements in the industry is the use of Expanded Polystyrene (EPS) geofoam as an alternative to traditional fill materials. Let’s explore how EPS geofoam compares to traditional fill and why it’s becoming a preferred choice for many projects.

What is EPS Geofoam?

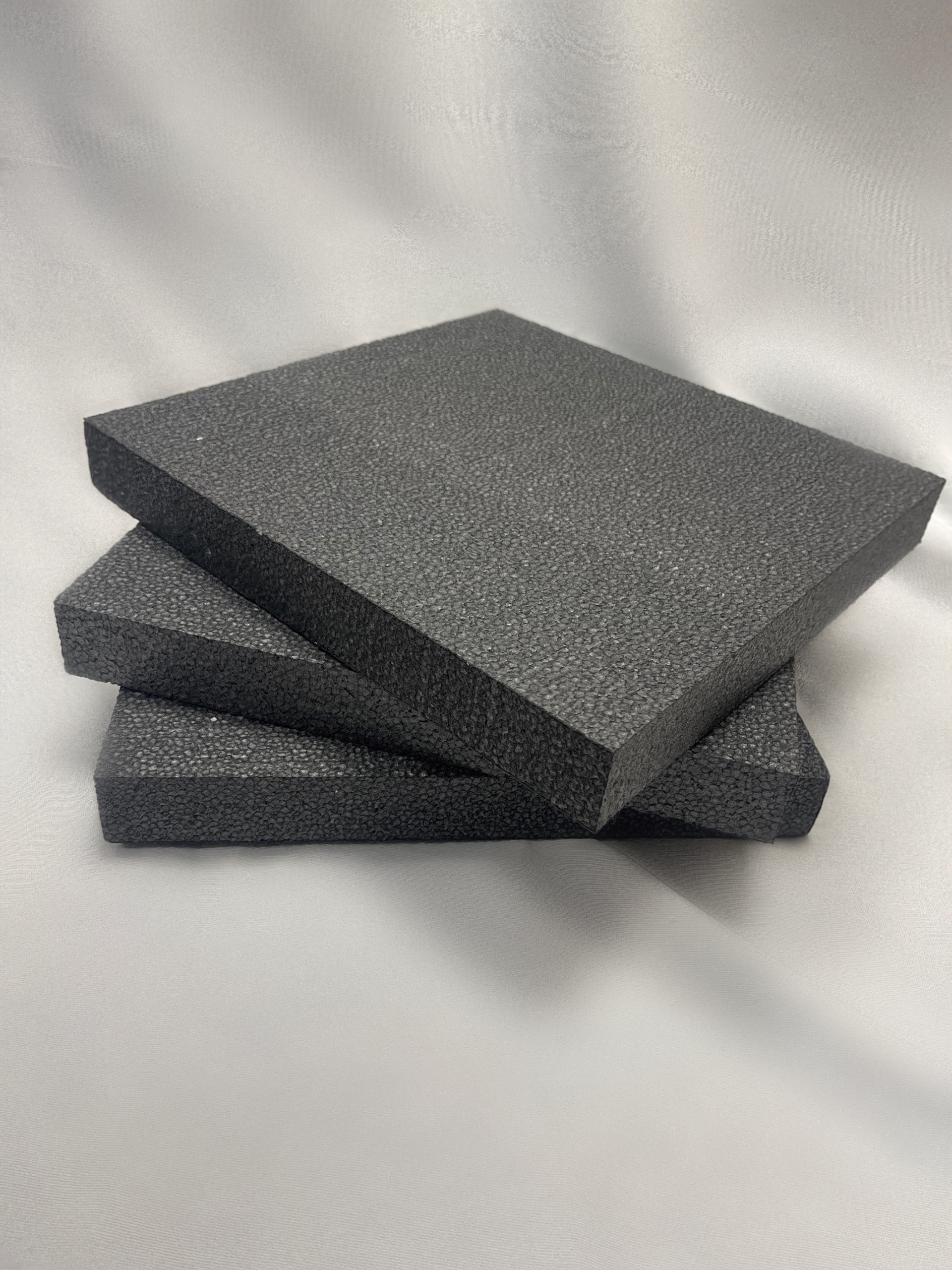

EPS geofoam is a lightweight, engineered material made from expanded polystyrene fill. It is primarily used as a lightweight fill in construction projects where reducing load is critical. Unlike traditional fill materials such as soil, sand, or gravel, EPS geofoam is pre-manufactured in block form and can be cut and shaped to meet project-specific requirements.

Advantages of EPS Geofoam

- Lightweight Properties

- EPS geofoam weighs approximately 1 to 3 pounds per cubic foot, compared to traditional fills, which can weigh up to 120 pounds per cubic foot. This extreme weight difference reduces the load on underlying structures, making it ideal for applications such as roadways, bridges, and retaining walls.

- Ease of Installation

- Due to its lightweight nature, EPS geofoam is easier to transport, handle, and install than traditional materials. This reduces labor costs and accelerates construction timelines.

- Reduced Settlement Risks

- Traditional fill materials can lead to settlement over time, especially in soft soil conditions. EPS geofoam, however, is dimensionally stable and does not settle, ensuring long-term performance and structural integrity.

- Customizable and Versatile

- EPS geofoam can be custom-fabricated to meet specific project needs, whether it’s shaping blocks for complex geometries or adjusting thickness and density for different load-bearing applications.

- Environmental Benefits

- EPS geofoam’s lightweight properties reduce the energy required for transportation. Additionally, its inert composition ensures it does not leach harmful chemicals into the environment.

Traditional Fill: Challenges and Limitations

While traditional fill materials have been used for centuries, they come with several drawbacks:

- High Weight and Load Impact

- The significant weight of traditional fills increases stress on underlying soil and structures, often requiring additional reinforcement or stabilization.

- Extended Installation Times

- Transporting and compacting large volumes of fill material is time-intensive, leading to longer project durations.

- Risk of Settlement

- Over time, traditional fills can compress or settle unevenly, leading to structural issues and increased maintenance costs.

- Environmental Concerns

- The extraction and transportation of traditional materials often have a higher environmental impact compared to EPS geofoam.

Applications of EPS Geofoam

EPS geofoam is used in a variety of construction projects, including:

- Road Construction: Reduces load on underlying soils, minimizing the risk of settlement.

- Bridges and Embankments: Provides lightweight support without overloading foundations.

- Retaining Walls: Acts as a backfill material to reduce lateral loads.

- Landscaping and Green Roofs: Offers lightweight elevation changes without stressing structural elements.

- Culverts and Utility Protection: Ensures even load distribution over sensitive infrastructure.

Cost Considerations

Although EPS geofoam may have a higher upfront cost per cubic foot compared to traditional fill materials, its long-term benefits often outweigh this initial expense. Reduced labor, faster installation, and minimal maintenance costs make EPS geofoam a cost-effective solution over the lifespan of a project.

Conclusion

EPS geofoam is transforming the construction landscape by providing a lightweight, durable, and versatile alternative to traditional fill materials. Its numerous advantages—including ease of installation, reduced settlement risks, and environmental benefits—make it an ideal choice for modern construction challenges. As more engineers and contractors recognize the benefits of EPS geofoam, its adoption will continue to grow, redefining standards in the construction industry.

To learn more about EPS geofoam, expanded polystyrene fill, construction foam, EPS blocks, and how they can benefit your next project, visit Poly Molding LLC or contact our team today.