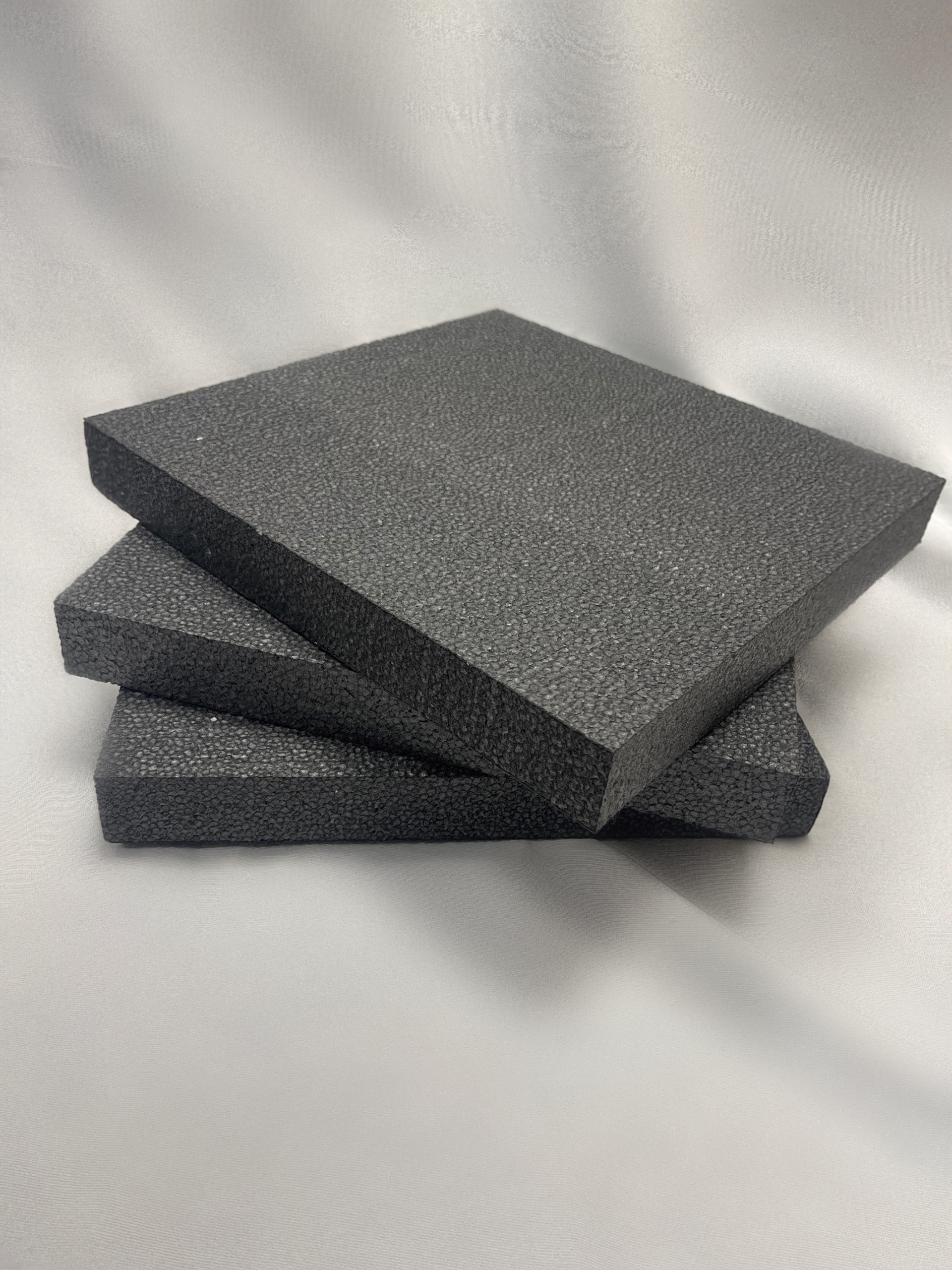

Geofoam, a lightweight, durable, and efficient material, is an excellent option to reduce project timelines and ease the site preparation process for commercial construction projects.

Geofoam, a type of foam foundation block, offers a variety of benefits and applications for construction projects. Contractors have used it to solve several challenges, including transforming steep-sloped lots into level building pads, stabilizing steep slopes, creating tiered theater/stadium seating, and soil remediation.

For instance, when making a slope level enough to place a foundation slab on it, geofoam can replace soil and dirt as a fill. Traditional soil and dirt require heavy equipment, additional labor, and months to settle, creating delays in the site preparation process. Geofoam, on the other hand, doesn’t settle like soil and dirt and is only 1% of their weight. Therefore, it doesn’t require compaction and reduces the need for heavy equipment, enabling faster and easier installation.

Additionally, geofoam’s light weight reduces the lateral load on the retaining wall, making it less expensive to build. It also resists the impact of earthquakes and tremors, making it a safer option in areas prone to natural disasters. Furthermore, when used for slope stabilization, geofoam reduces overall slope weight, decreasing the pressure and load against the hillside.

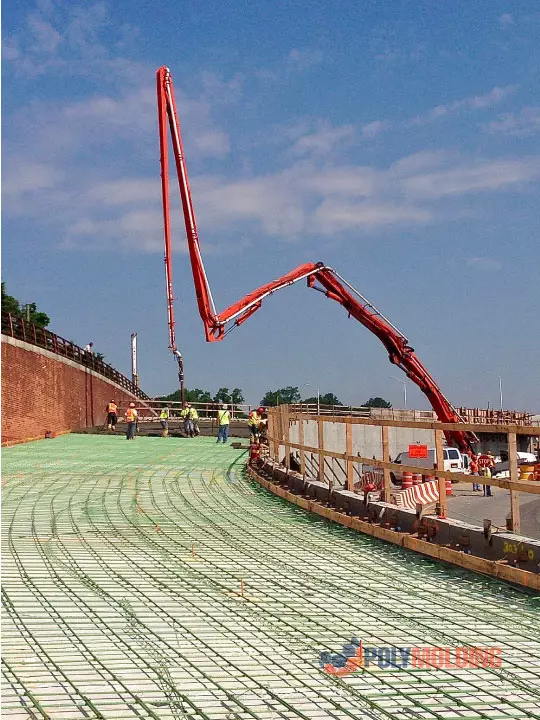

In the case of tiered theater/stadium seating, using geofoam blocks instead of soil or dirt eliminates the need for tier compacting, making the process much simpler and faster. Geofoam blocks are easily cut to size, allowing for on-the-fly tweaks to the job if necessary.

In summary, geofoam can significantly reduce the time it takes to complete site preparation for commercial construction projects, while also offering ease of installation, cost savings, durability, and longevity. By using this material, contractors can avoid the headache of slow-moving projects and ensure a smooth and timely construction process.