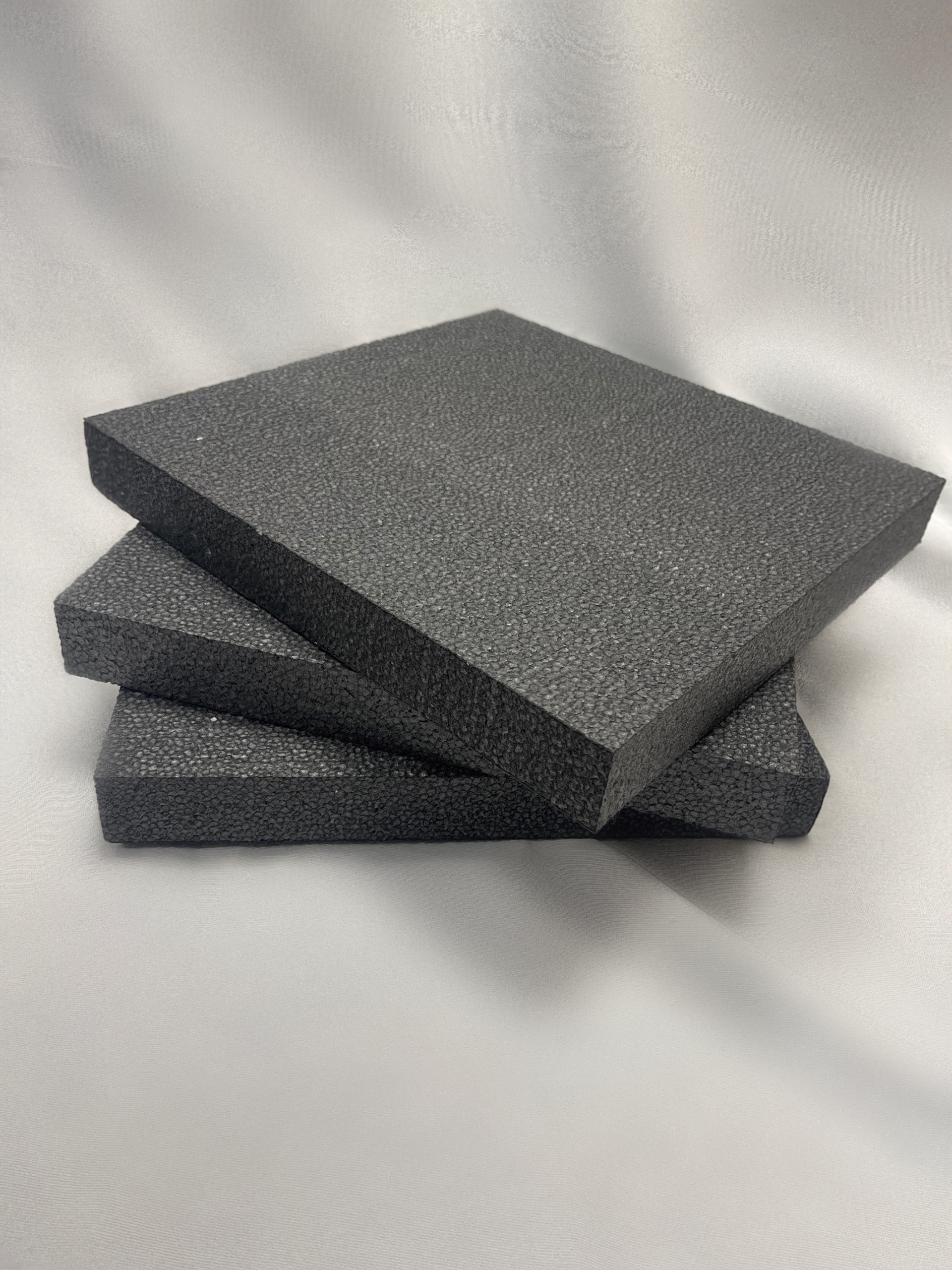

When it comes to heavy construction or deep excavation projects requiring significant support systems think of flute fillers and secant walls, then think of Poly Molding. Among a catalog of products some of our most popular (depending on the season) happen to be flute fillers and secant piles made from Geofoam.

Flute Fillers Save Weight and Money

The construction of this bridge in Haverhill Mass. Spanning the Merrimack River included the use of 2,000 pounds of Geofoam. This project is a remarkable example of the cost savings and durability that Geofoam brings to a project. As explained in a downloadable guide here you can find some valuable information to consider for your next project. Expanded Polystyrene, Geofoam comes in a variety of shapes, densities, and sizes. Although the 2,000 pounds of Geofoam may sound significant, it’s nothing when you consider it saved more than 340,000 pounds of concrete. Flute fillers for bridges are not anything new, and lightweight EPS is used to lessen the overall load and supply the density needed for just about any commercial vehicle on the road today.Flute fillers are ordered from production houses like Poly Molding pre-measured and styled by the architect and construction head. When you consider that one cubic foot of Geofoam weighs only one pound, the cost savings are huge. Yet, using flute fillers does nothing to lessen the integrity of the overall project. Imagine the cost savings to the local government and taxpayers when using flute fillers in projects such as these.We all know the infrastructure of this nation is aged, and in a great many locations, roadways and bridges need repairs or replacement. The US Government identified more than 55,000 bridges in the United States. The budget over the next 15 years or less can be as much as $20 Billion. That’s with a “B.”It only makes great sense to look to EPS Geofoam as the tremendous cost savings it brings to infrastructure to repairs and replacements.

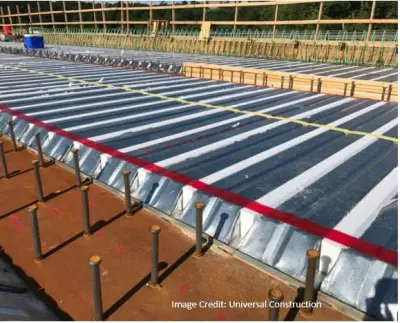

FLUTE FILLERS BEING UTILIZED IN BRIDGE CONSTRUCTION PROJECT

SECANT PILE CYLINDRICAL FORMS, CHICAGO, IL.